The simplest roof design strategy is to install all insulation layers on top of the roof deck. One system repeated is faster, better and less expensive than multiple components requiring multiple details.

Based on our review, the Quik-Therm Matrix Insulated Roofing System will be able to resist the loads as outlined in the National Building Code of Canada for typical, moderately tall buildings throughout Canada….

– Morrison Hershfield

Technical Downloads

* Patent Pending

Design & Install Guidelines

Case Studies

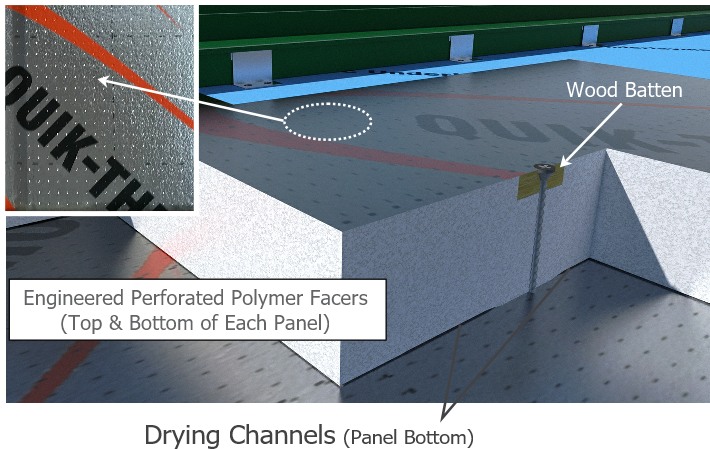

Built-in Furring & Self Drying

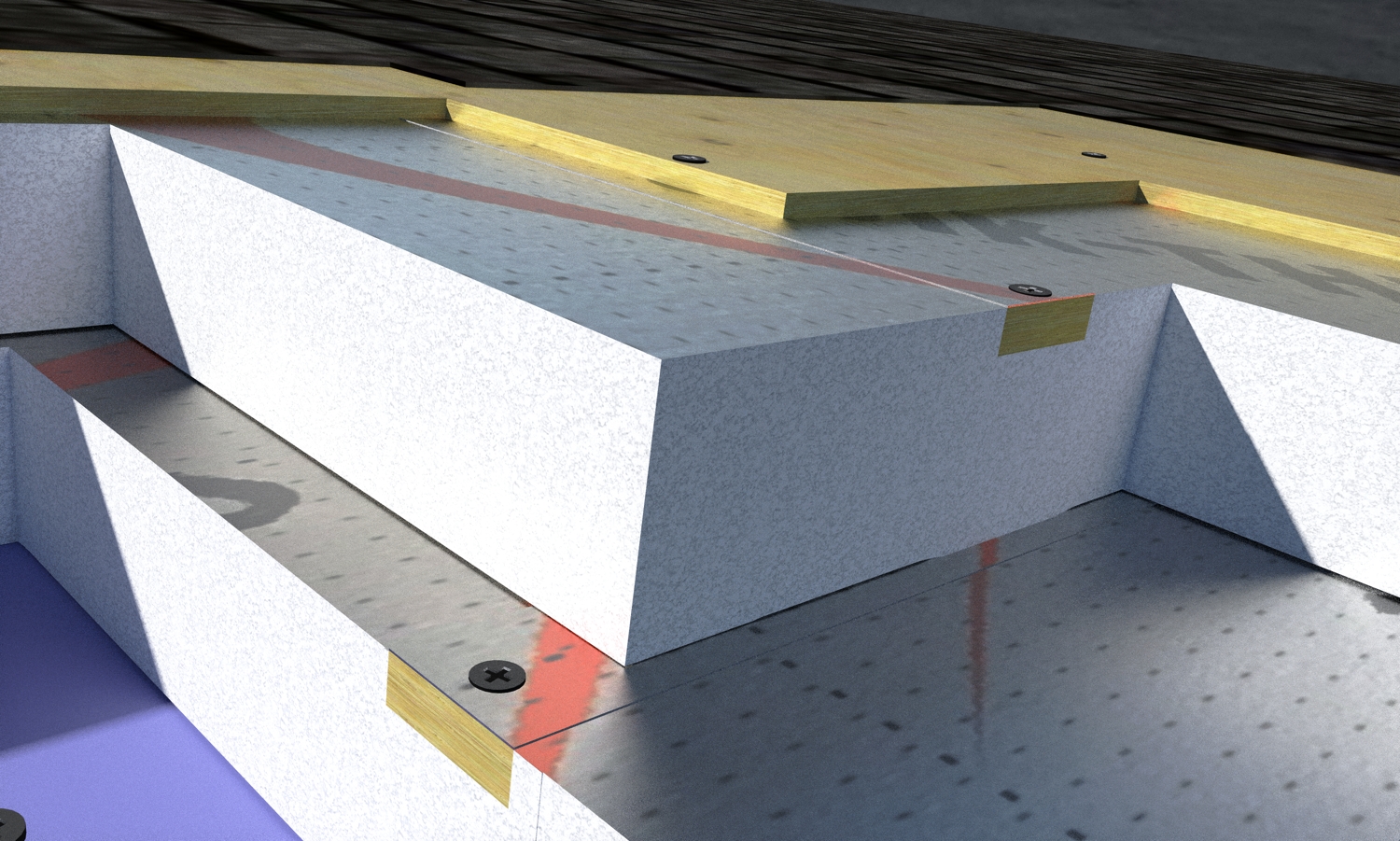

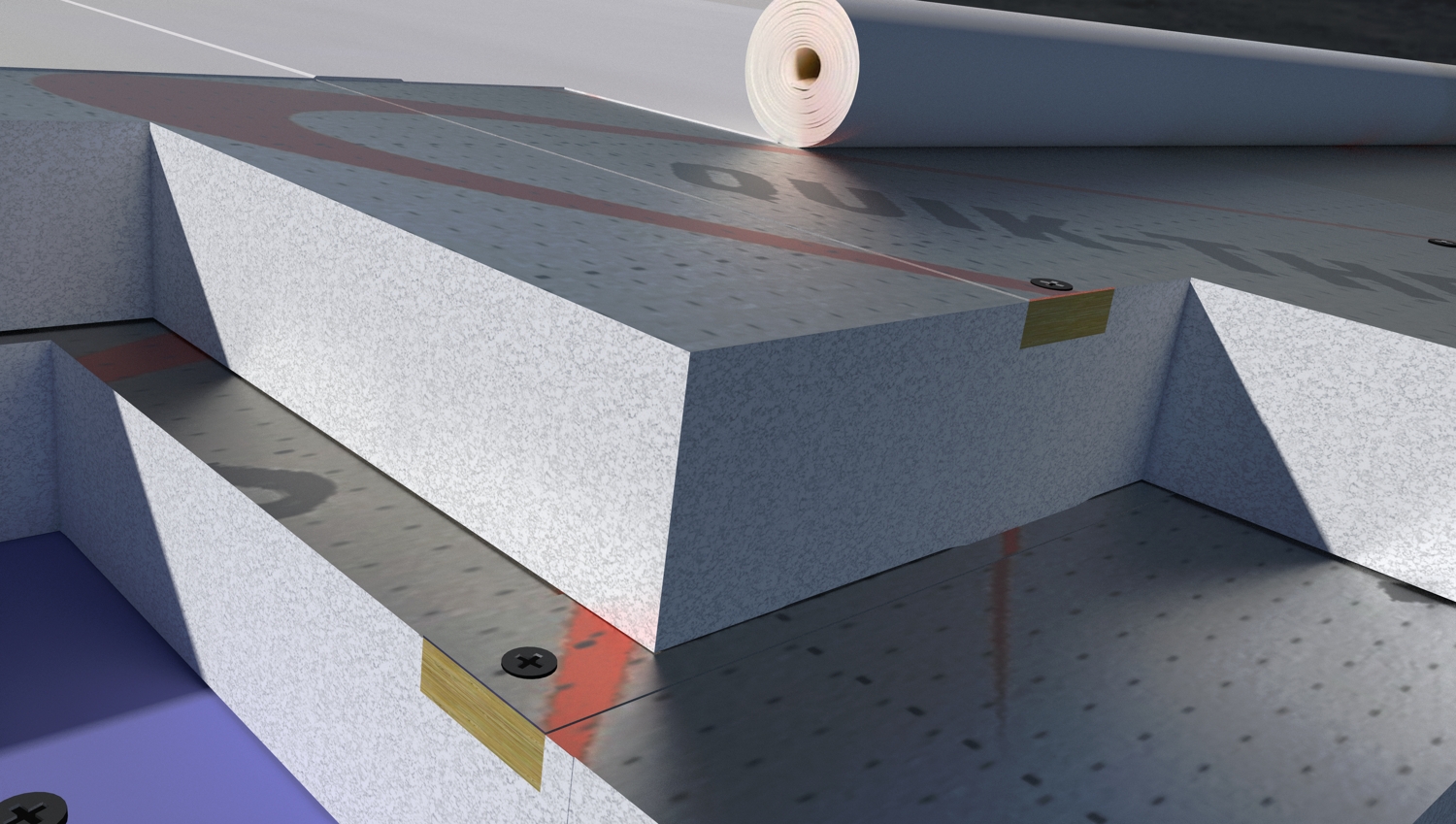

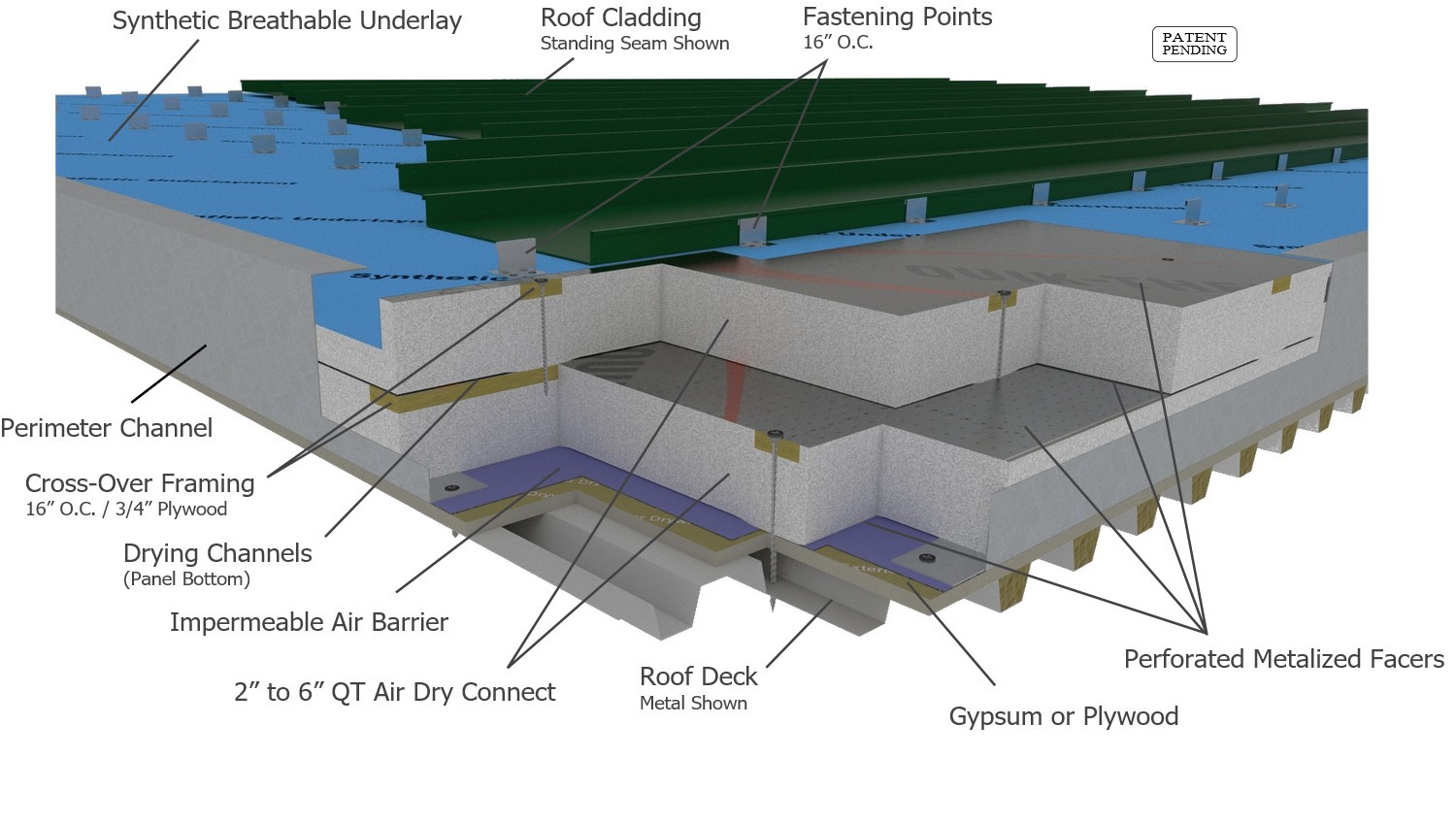

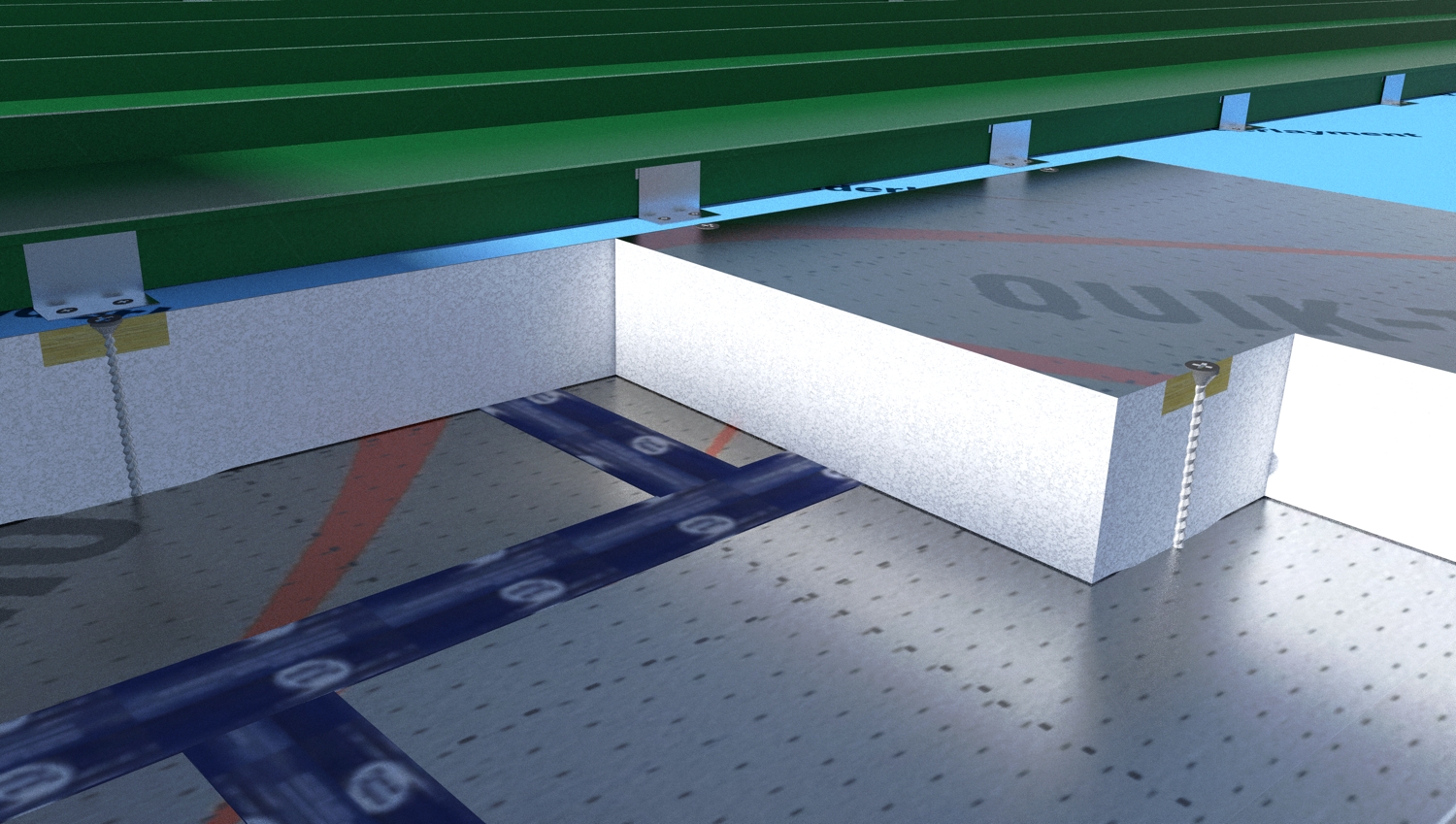

Matrix is a Patent Pending science based roofing insulation system. Matrix consists of two or more layers of Quik-Therm Air Dry Connect. The bottom layer runs peak to eave (high to low) and the top layer runs gable to gable (side to side). Spaced 16” OC., 3 precision 3/4” thick x 3” wide plywood battens or optional steel furring is embedded into Type 2 EPS panels. Unobstructed drying channels are located on the bottom panel side. Perforated, Low E like polymer facers are laminated to both sides of the panels.

* Patent Pending

The orthogonal support provided by the cross-over framing will aid in the overall stability of the system.

– Morrison Hershfield

Robust, Lightweight & Stable

Precision cross-over, staggered joint connection design provides superior structural integrity. The clamping, pre-tension fastening system minimizes expansion, contraction and cupping. Type 2 EPS compressive strength @2,800 lbs/ft2. Laminated polymer films provide added impact and foot traffic resistance. Mechanically fastened. No adhesives required.

Virtually 100% Thermal Bridge Free - Including Fasteners

Matrix’s effective R-value performance is superior to conventional Clip and Rail and Continuous Steel Girt systems. Plywood battens or steel furring and fasteners are covered by, or encapsulated within Matrix’s EPS foam core. As a consequence – the potential for interior dripping, fastener corrosion, material degradation and mold are substantially mitigated.

Quik-Therm Insulation Solutions Inc. has undertaken a program of full scale thermal performance testing to ASTM C1363-05 Standard Test Method for Thermal Performance of Building Materials and Envelope Assemblies. Testing confirmed the presence of the shallow flutes and plywood furring strips did not significantly affect the thermal performance of the assembly when compared to the assembly containing Quik-Therm Multi-Purpose Insulation.

– Morrison Hershfield

* Patent Pending

Manages Bulk Water Intrusion & Vapour Diffusion

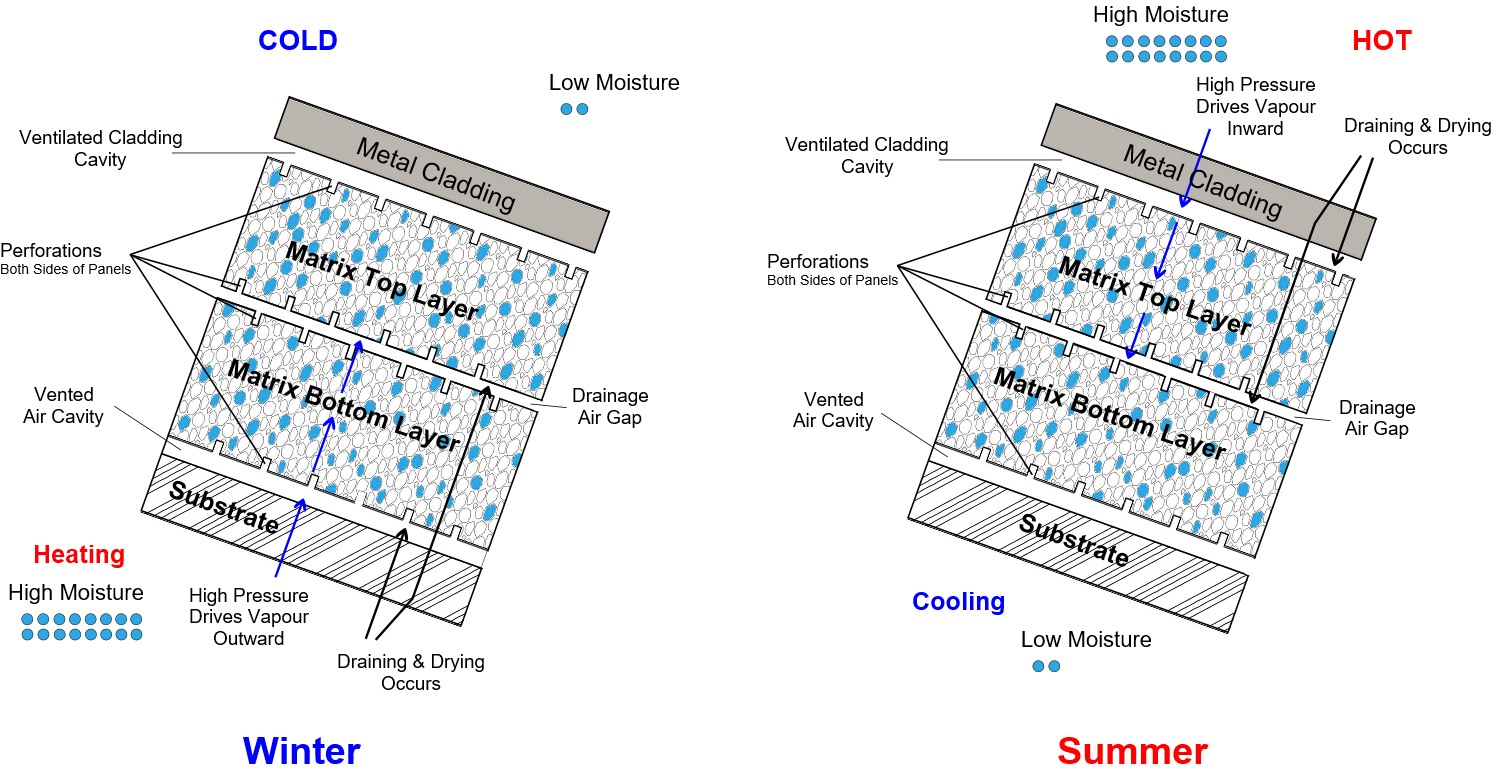

Matrix is self drying. Shallow, free air, unobstructed venting encourages outward bulk water drainage and drying. Engineered perforations allow vapour to diffuse naturally to the vented air gaps and surrounding ambient air. Low emissivity (Low E), foil like metalized polymer facers reduce inward vapour solar drive. Matrix’s unique drying ability mitigates the potential for mold and material degradation.

“The air-gap is simple, elegant and unbelievably effective in helping out drying.”

– Joe Lstiburek PhD, P. Eng., Building Science Corporation, Mind the Gap, Eh!

Installs Intuitively, Fast and Easy

All in one installation. Precision built-in plywood furring strips. Visual 16” O.C. connection points. 8” O.C. grid lines. Tongue & groove panel connections. Lightweight and durable 4×8 panels cover 32 sq. ft.. 2” to 6” thicknesses. Superior tape adhesion. No adhesives required.

Compatible With Adhered Membranes

Exceeds Up Lift resistance requirements. Test procedure TAS Standard 124-95. Most adhered membranes can be installed directly on top of the Matrix system. Watch the test video.

7 Most Commonly Asked Questions

1. What are the best roofing applications for Matrix?

A. Matrix was designed specifically for screw down and standing seam metal cladded roofs. Alternative roof cladding materials may require a wood substrate fastened to the 3/4” built-in plywood battens.

2. Explain how the Matrix Roofing Insulation System is thermal bridge free including fasteners?

A. The bottom layer of Air Dry Connect panels are fastened through the plywood furring/battens directly to the roof deck. Battens in the top layer fasten directly to battens in the bottom layer. As a result, fasteners from the top layer end up “stalled” inside the rigid foam insulation of the bottom layer and do not touch the roof deck. To summarize; top layer battens and fasteners are covered by the top layer of Air Dry Connect insulation. The points of all fasteners from the top layer are encapsulated within the rigid foam insulation of the bottom layer.

3. Why does the Matrix roofing insulation system utilize 3/4” plywood furring rather than typical 18 gauge steel C channels or Z-bars?

A. Compared to 18 gauge steel, 3/4” plywood has superior pull out resistance. Plywood is easier to cut than 18 gauge steel. 3/4” plywood is thicker than steel. As a result, fasteners are less likely to strip. There is minimal thermal bridging with plywood. Plywood is less expensive than steel. There is less potential for condensation with plywood. Contractors prefer working with plywood vs. steel.

4. Do the same laws of physics apply to both roofs and walls?

A. Yes. Walls are roofs and roofs are walls. “The same approaches can be applied to both walls and roofs – the argument being that similar loads and the same laws of physics apply.” – BSI-090: Joseph Haydn Does The Perfect Wall – Building Science Corporation

5. What is the purpose of Matrix’s drainage plane gap and perforations?

A. Combined; think of the gap and perforations as a built-in safety valve. Some water – somehow, always finds its way into the building envelope. When moisture gets trapped, drying of the assembly is impeded. As a consequence, an environment for material degradation and mold is created. Free air, unobstructed drainage channels promote outward drainage and drying. Engineered perforations in the polymer facers allow water vapour to diffuse naturally and safely, into and through Matrix’s EPS foam insulation panels. In essence, the Matrix roof assembly is basically self drying. LEARN MORE

6. What is a Hygrothermal Analysis?

A. Built Environments Inc. states: “A Hygrothermal analysis pertains to the movement of heat and moisture through buildings. Computer-based modeling offers highly accurate predictions of hygrothermal performance for preventing early degradation and reduced service life.”

7. Does the Matrix drainage plane air gap reduce Matrix’s thermal performance?

A. The gap has virtually no effect on R-value performance. “Testing included direct comparison of assemblies with Solar-Dry and Quik-Therm Connect product that is similar but without the flutes [air gaps].” “Tests confirmed the introduction of the 3/16" flutes and [2-1/2] wood furring had no appreciable effect on the thermal performance of the wall assembly, provided that the flutes are sealed at the top of each wall panel to eliminate convection air currents.” – Mark Lawton, P.Eng, Senior Building Scientist, Morrison Hershfield. “The predicted reduction in thermal efficiency was less than 1%.” – Steven Doggett, PhD., LEED, Built Environments Inc.

Environment. Sustainability. Health.

Quik-Therm’s expanded polystyrene foam (EPS) core comprises of 98% air captured within a 2% cellular matrix. Food grade quality polymer facers are heat sealed to both sides of it’s core. Water used in the manufacturing process is recycled and re-used many times over. Quik-Therm will not degrade and does not contain or use ozone depleting chemicals. Quik-Therm may contain up to 15% pre or post consumer recycled EPS. EPS has received an A+ rating for most environmental matrices.

Structural & Engineering

Has the Matrix cross over clamping fastening design been engineered for fastener pull out resistance, wind uplift and snow loads?

A. Yes. Morrison Hershfield provided a complete engineering evaluation for the Matrix roofing system. https://quiktherm.com/wp-content/uploads/2020/01/Quik-Therm-Matrix-Structural-Review-Letter_final.pdf.

Do the embedded plywood furring strips/battens and laminated facers increase the structural integrity of the Matrix roofing insulation system?

A. Inserting furring strips directly into the EPS foam panel slots eliminates lateral movement and shifting of plywood battens. Matrix’s polymer facers combined with the fastener clamping design, virtually eliminates distortion (creeping), cupping and warping of the Connect Air Dry panels. Morrison Hershfield: “The orthogonal support provided by the cross-over framing will aid in the overall stability of the system.”

Can the 3/4” plywood battens be replaced with 18 gauge steel C channels?

A. Yes. The plywood battens can be replaced with 18 gauge steel C channels. Just like the plywood battens, the C channels are embedded into the EPS foam panels. Channel face width 3”, with 1/2” legs. 18 gauge C channels are more expensive than 3/4” x 3” wide plywood battens.

Does the Matrix roofing insulation system install faster and more efficient than conventional rigid insulation roof designs?

A. Yes, much faster. The simplest roof design strategy is to install all insulation layers on top of the roof deck. One system repeated is much faster and easier to construct than multiple components requiring multiple details. Matrix is a composite design ie: – insulation and framing are combined as one. No girts or clips. 4×8 panels install faster than 2×8 panels. Lightweight and durable. Minimal detailing required.

Hygrothermal Performance

What is the most basic Building Science fundamental I need to understand?

A. Heat migrates to cold, high pressure moves to low pressure, high moisture flows to low moisture, air aids drying/evaporation, gravity aids drainage. Pressure drives heat and moisture outward during the winter and inward during the summer.

From a building science perspective are roofs walls and walls roofs?

A. Yes. The same approaches can be applied to both roofs and walls. “The argument being that similar loads and the same laws of Physics apply.” – BSI – 090: Joseph Hayden Does The Perfect Wall – Building Science Corporation.

Why has the focus on moisture management become so prevalent?

A. 90% of all building envelope problems are related to water. Designing for moisture management is important to protect the building and keep its occupants safe from adverse health effects. “The harmful effects of water on building materials can hardly be over-emphasized. If they did not exist, the construction of durable buildings would be greatly simplified and the task of the designer and contractor made much easier.”- CBD-30. Water and Building Materials, National Research Council Canada

What is a Hygrothermal Analysis?

A. “A Hygrothermal analysis pertains to the movement of heat and moisture through buildings. Computer-based modeling offers highly accurate predictions of hygrothermal performance for preventing early degradation and reduced service life.” – Built Environments Inc.

What effect does construction moisture have on buildings?

A. Construction moisture is a major problem in buildings. Natural Resources Canada states: “The harmful effects of water on building materials can hardly be over-emphasized. If they did not exist, the construction of durable buildings would be greatly simplified and the task of the designer made much easier.”

What is a drainage plane?

A. A drainage plane is a small, unobstructed air gap that runs from top to bottom of a wall or roof assembly. Drainage gaps promote outward drainage and drying (evaporation). A drainage plane gap mitigates the wetting potential of inner portions of the assembly. As a result, the negative effects of material degradation and mold are reduced. Unobstructed, free air drainage gaps allow roofs and walls to become self drying.

How does the small air gap enhance the drainage and drying ability of the Matrix roofing insulation system?

A. Air naturally promotes drying – gravity naturally encourages drainage. To prove the concept and design, Quik-Therm commissioned RDH Building Science Laboratories and Morrison Hershfield to test and analyze the drainage and drying ability of QT Solar Dry Insulation System. RDH stated; “The excellent drainage performance and improvement in drying within the vented cavity of the wall assembly constructed with SDI reduces moisture durability risks of the enclosure that could result from water getting trapped and held between the components of the wall assembly.”

Since a vertical wall drains bulk water faster than a sloped roof, bulk water drainage of the Matrix roofing insulation system would occur at a slower rate than the Solar Dry wall assembly. Matrix is a self drying roof assembly – its just slower than Solar Dry.

Does the Matrix roofing insulation system require a synthetic underlayment between it and metal roof cladding?

A. Yes. Buildings absorb radiant heat during the day. At night, they give off heat to the colder night sky – referred to as night sky radiation. As a result, condensation occurs between the metal roof cladding and the Matrix system. A low cost, breathable synthetic underlay is recommended between the Matrix system and metal roof cladding.

Thermal Performance

How does Matrix’s R-value performance compare to conventional roofing insulation systems?

A. Matrix offers superior R-value performance. Learn More

What is the nominal R-value of the Matrix Roofing Insulation System?

A. Type 2: R-4.18 per inch. However, as tested to the ASTM C1363 effective R-value standard, Air Dry Connect’s R-value performance was superior to its labeled R-value.

Has Quik-Therm tested to the Effective R-value standard ASTM C1363?

A. Yes. Quik-Therm Insulation Solutions Inc. has undertaken a program of full scale thermal performance testing to ASTM C1363-05 Standard Test Method for Thermal Performance of Building Materials and Envelope Assemblies by Means of a Hot Box Apparatus. Over 30 wood frame, concrete and steel frame assemblies have been tested to ASTM C1363.

How is the effective R-value for the Matrix roofing insulation system calculated?

A. The nominal R-value for Matrix is R-4.18 per inch. Since there is no penalty for thermal bridging degradation, it’s effective R-value is identical to its nominal R-value, plus air films and applicable building materials. For example, to achieve an effective R-28.5 for a cathedral style roof assembly, two layers of 3.25” thick Air Dry Connect would be required. R-4.18 x 6.5 = 27.17. Add approximately R-2 for air films and components = Effective R-29.17.

Does the Matrix drainage plane air gap reduce Matrix’s thermal performance?

A. The gap has virtually no effect on R-value performance. “Testing included direct comparison of assemblies with Solar-Dry and Quik-Therm Connect product that is similar but without the flutes [air gaps].” “Tests confirmed the introduction of the 3/16" flutes and [2-1/2] wood furring had no appreciable effect on the thermal performance of the wall assembly, provided that the flutes are sealed at the top of each wall panel to eliminate convection air currents.” – Mark Lawton, P.Eng, Senior Building Scientist, Morrison Hershfield. “

“The predicted reduction in thermal efficiency was less than 1%.” – Steven Doggett, PhD., LEED, Built Environments Inc.

Thermal Bridging

Explain how the Matrix Roofing Insulation System is thermal bridge free including fasteners?

A. The bottom layer of Air Dry Connect panels are fastened through the plywood furring/battens directly to the roof deck. Battens in the top layer fasten directly to battens in the bottom layer. As a result, fasteners from the top layer end up “stalled” inside the rigid foam insulation of the bottom layer and do not touch the roof deck. To summarize; top layer battens and fasteners are covered by the top layer of Air Dry Connect insulation. The points of all fasteners from the top layer are encapsulated within the rigid foam insulation of the bottom layer.

How much do continuous steel girts degrade the effective R-value performance of rigid continuous insulation systems?

A. A lot. “The cladding attachment can be a significant thermal bridge and reduce exterior insulation performance by as much as 80% for poor systems” – Cladding Attachment Solutions for Exterior Insulated Commercial Walls. – Graham Finch, Dipl.T, MASc, P.Eng. & James Higgins, Dipl.T., RDH Building Science Laboratories. “Vertical continuous Z-girts […] resulted between 77% and 84% thermal degradation for the steel stud backup wall.”

How much do clip and rail (girt) systems degrade the effective R-value performance of continuous rigid insulation systems?

A. It depends on the clip type and spacing. “Each proprietary system will have different thermal performance characteristics and may require thermal modeling to determine the overall thermal performance of the wall assembly. Most high-performance clip systems will result in less than 30% thermal degradation of the exterior insulation (i.e. 70% effectiveness of the exterior insulation).” – Illustrated Guide to R22+ Effective Walls, Published by BC Housing – page 13.

Do fasteners negatively affect the thermal performance of insulated roof assemblies?

A. Yes. Fastener thermal bridging, referred to as “point bridging” can significantly reduce the effective R-value of insulated assemblies. “With the steel plate above the polyisocyanurate cover board, the fastener and plate drop the R-value from R-29.0 to R-21.2. This is a 27% reduction in R-value as compared to the nominal R-value using polyisocyanurate cover board.” – Eric K. Olson, P.Eng., Associate Principal, Simpson Gumpertz & Heger Inc.

Code Compliance

Is wood furring code compliant with steel framed roof assemblies?

A. Yes. The code allows wood furring, framing or sheathing with rigid foam insulation over steel framed roofs. (NBCC Article 3.1.5.3.)

Is the Matrix roofing insulation system code compliant for non-combustible buildings?

A. Rigid foam insulation is permitted to be installed above roof decks, below grade foundation walls and concrete slabs. (NBCC Article 3.1.5.15.)

Does the Matrix roofing insulation system require a fire rated thermal barrier?

A. Yes. Quik-Therm EPS rigid foam insulation used in wall, roof or ceiling applications is required to be protected by one of the following options:

- As described in Subsections 9.29.4 to 9.29.9. Plaster, Gypsum Board with taped joints, Concrete, Plywood, Hardboard, Fibreboard, Particleboard, OSB, or Waferboard.

- Sheet metal if it is at least 0.38 mm thick.

- For some applications and non-combustible buildings, other requirements may apply.

Do Matrix’s foil facers achieve code compliance as weather resistant barrier’s (WRB)?

A. Yes. Second plane of defense. (NBCC Article 9.27.3.3.)

Do all insulation products perform at their published labeled R-value’s?

A. No. At cold temperatures, Fiberglass, Mineral Wool, XPS and EPS perform slightly better than their published R-value’s. Polyisocyanurate, on the other hand performs worse than its published R-value, especially in cold climates. RDH Building Science Laboratories states that Polyisocyanurate lost 10% of its nominal R-value at mean 75°F and showed decreases of up to 20% after being aged in the field for three years. “Testing shows Polyiso’s R-value decreases as temperatures get colder. The relationship between temperature and R-value appears to be non-linear (i.e. it’s not a simple straight line) so the mean temperature R-value tests cannot easily be used to predict in-service performance.” – Info-502: Temperature Dependence of R-values in Polyisocyanurate Roof Insulation, Building Science Corporation

Building Science Basics

What is the most basic Building Science fundamental I need to understand?

A. Heat migrates to cold, high pressure moves to low pressure, high moisture flows to low moisture, air aids drying/evaporation, gravity aids drainage. Pressure drives heat and moisture outward during the winter and inward during the summer.

Do the same laws of physics apply to both roofs and walls?

A. Yes. Walls are roofs and roofs are walls. “The same approaches can be applied to both walls and roofs – the argument being that similar loads and the same laws of physics apply.” – BSI-090: Joseph Haydn Does, The Perfect Wall, Building Science Corporation

Why has the focus on moisture management become so prevalent?

A. 90% of all building envelope problems are related to water. Designing for moisture management is important to protect the building and keep its occupants safe from adverse health effects. “The harmful effects of water on building materials can hardly be over-emphasized. If they did not exist, the construction of durable buildings would be greatly simplified and the task of the designer and contractor made much easier.”- CBD-30. Water and Building Materials, National Research Council Canada

What is a double vapour barrier?

A. A double vapor barrier is a building assembly, wall or roof constructed with two relatively vapor impermeable materials that enclose other building materials. If moisture gets trapped between the two vapor retarders the drying process will be extremely slow. As a consequence, the enclosed materials may achieve moisture levels that will result in mold growth and/or structural decay.

What is the difference between Absorption and Adsorption?

A. Absorption (absorbent) is the manner in which a fluid is dissolved in a solid i.e. water soaked up by a paper towel. Adsorption occurs on the surface of a material. The liquid clings to the surface but does not soak into the material i.e. water molecules (condensation) on window glass.

What is the difference between permeance vs. permeability?

A. Vapour Permeance is time it takes water vapour to transmit through a material that has a vapour pressure difference between the two exposed surfaces of the material. It is normally expressed as Perm. Vapour Permeability is the measure of the resistance of water vapor to pass through a material. Vapour permeability relates to water in its gas form.

Is rigid foam insulation a vapour barrier?

A. No. “There is a prevailing misconception exists in understanding how water vapor moves through closed-pore foam insulation. It originates from the assumption that if foam insulation absorbs very little liquid water and is only semi-permeable to vapor, it must therefore function as a vapor barrier. Below I address this fallacy with a simple analogy, the bucket brigade. Closed pore foam insulation is moderately hygroscopic which means it ADSORBS water vapor from its ambient environment. Diffusion through the closed pore matrix occurs when ADSORBED water molecules nearest the moisture gradient source are safely “ handed off’ to its adjacent downstream surface. This process continues down a vapor pressure gradient, thereby establishing the bucket brigade. Instead of transporting liquid water, the ‘buckets’ (i.e. hygroscopic surfaces) contain water vapor […]” – Steven Doggett, PhD, LEED, Built Environments Inc.

Why are rigid foam insulation manufacturers starting to incorporate drainage spaces (air gaps) in their products? (i.e. EIFS)

A. Managing moisture is about removing bulk water and water vapor from wall and roof assemblies before they cause damage. This is achieved by deflection, drainage and drying and durability of materials. Joseph Lstiburek, Ph.D., P.Eng., from the Building Science Corporation, states it this way. “The air-gap is simple, elegant and unbelievably effective in helping out drying.” BSI-038: Mind the Gap, Eh!

Does a drainage / drying plane air gap between the exterior substrate and rigid foam insulation degrade the thermal performance of the assembly?

A. No. “Testing included direct comparison of assemblies with Solar Dry and the Quik-Therm Connect product that is similar but without the flutes [air gaps]. Tests confirmed the introduction of the 3/16" flutes and [2-1/2] wood furring had no appreciable effect on the thermal performance of the wall assembly, provided that the flutes are sealed at the top of each wall panel to eliminate convection air currents.” – Mark Lawton, P.Eng, Senior Building Scientist, Morrison Hershfield. “The predicted reduction in thermal efficiency was less than 1%.” – Steven Doggett, PhD, LEED, Built Environments Inc.

Do all insulation products perform at their published labeled R-value’s?

A. No. At cold temperatures, Fiberglass, Mineral Wool, XPS and EPS perform slightly better than their published R-value’s. Polyisocyanurate, on the other hand performs worse than its published R-value, especially in cold climates. RDH Building Science Laboratories states that Polyisocyanurate lost 10% of its nominal R-value at mean 75°F and showed decreases of up to 20% after being aged in the field for three years. “Testing shows Polyiso’s R-value decreases as temperatures get colder. The relationship between temperature and R-value appears to be non-linear (i.e. it’s not a simple straight line) so the mean temperature R-value tests cannot easily be used to predict in-service performance.” – Info-502: Temperature Dependence of R-values in Polyisocyanurate Roof Insulation, Building Science Corporation

How much do continuous steel girts degrade the effective R-value performance of rigid continuous insulation systems?

A. “The cladding attachment can be a significant thermal bridge and reduce exterior insulation performance by as much as 80% for poor systems” – Cladding Attachment Solutions for Exterior Insulated Commercial Walls. – Graham Finch, Dipl.T, MASc, P.Eng. & James Higgins, Dipl.T., RDH Building Science Laboratories. “Vertical continuous Z-girts […] resulted between 77% and 84% thermal degradation for the steel stud backup wall.”

How much do clip and rail (girt) systems degrade the effective R-value performance of continuous rigid insulation systems?

A. “Each proprietary system will have different thermal performance characteristics and may require thermal modeling to determine the overall thermal performance of the wall assembly. Most high-performance clip systems will result in less than 30% thermal degradation of the exterior insulation (i.e. 70% effectiveness of the exterior insulation).” – Illustrated Guide to R22+ Effective Walls, Published by BC Housing – page 13.

Do fasteners negatively affect the thermal performance of insulated roof assemblies?

A. Yes. Fastener thermal bridging, referred to as point bridges can significantly reduce the effective R-value of insulated assemblies. “With the steel plate above the polyisocyanurate cover board, the fastener and plate drop the R-value from R-29.0 to R-21.2. This is a 27% reduction in R-value as compared to the nominal R-value using polyisocyanurate cover board.” – Eric K. Olson, P.Eng., Associate Principal, Simpson Gumpertz & Heger Inc.

The Environment

Are Quik-Therm insulation products environmentally responsible?

A. Quik-Therm’s expanded polystyrene (EPS) core comprises of 98% air captured within a 2% cellular (plastic) matrix. Food grade quality polymer facers are heat sealed to both sides of it’s core. Water used in the manufacturing process is recycled and re-used many times over. Quik- Therm will not degrade and does not contain or use ozone depleting chemicals. Quik-Therm may contain up to 15% pre or post consumer recycled EPS. EPS has received an A+ rating for most environmental matrices.