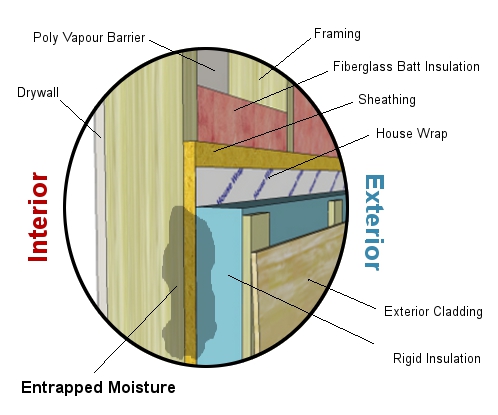

Double vapour barrier traps moisture in walls

Moisture management is the single most important factor in the design and construction of sustainable buildings and mold control. Approximately 90% of all building construction problems are related to water.

* Patented

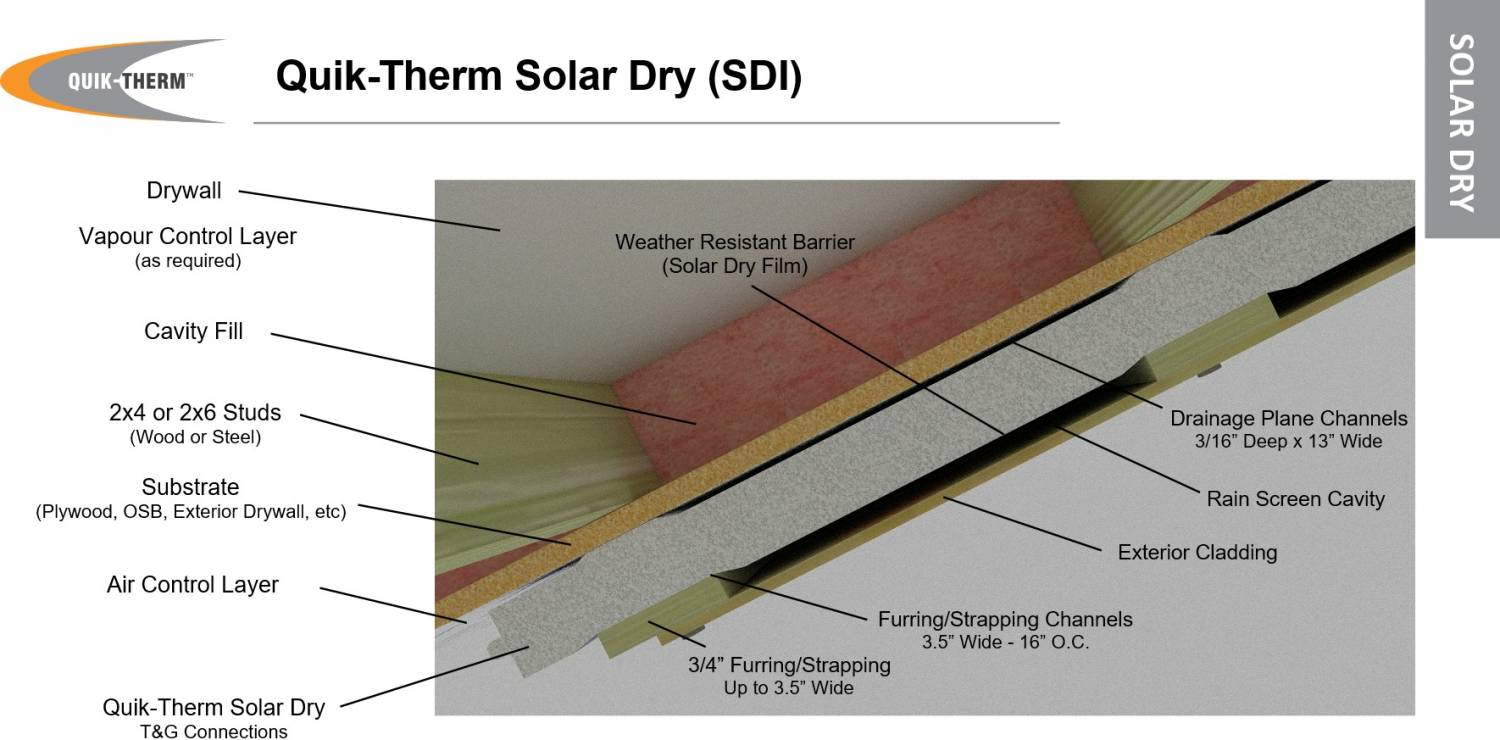

Quik-Therm Solar Dry (SDI)

Quik-Therm Solar Dry (SDI) is a Patented continuous rigid insulation with drainage gap. It’s a perforated foil insulation system with built-in drainage and drying capability. Solar Dry walls breathe, dry and drain bulk water to the outside. Solar Dry (SDI) is manufactured with engineered perforated metallic polymer facers laminated to closed-cell, lightweight Type 2 Expanded Polystyrene foam with drainage plane (EPS).

Solar Dry Walls Will Not Trap Moisture

The perforated SDI insulation system has a higher tolerance to rain penetration than any of the other walls evaluated in this analysis …

– Morrison Hershfield

The excellent drainage performance and improvement in drying within the vented cavity of the wall assembly constructed with SDI reduces moisture durability risks of the enclosure that could result from water getting trapped and held between the components of the wall assembly.

– RDH Building Science Laboratories

Perforations in the polymer facer of the Quik-Therm SDI insulation improves the hygrothermal performance of split insulated wood frame wall assemblies, especially with regard to the ability to dry out moisture from rain leaks and high construction moisture.

– Morrison Hershfield

In all instances, moisture levels were maintained below critical thresholds associated with mold growth and material degradation.

– Built Environments Inc.

“Both high and low-permeance exterior insulation can improve energy efficiency and durability. At the same time, each must be used appropriately to avoid moisture-related issues such as mold. For high-permeance insulation (i.e., mineral wool), the main concern is inward vapor drive; for low-permeance insulation (e.g., XPS, foil-faced polyiso), the concern is trapping water against sheathing."

– RDH Building Science Laboratories

Cold climate tested

Quik-Therm Insulation Solutions Inc. has undertaken a program of full scale thermal performance testing to ASTM C1363-05 Standard Test Method for Thermal Performance of Building Materials and Envelope Assemblies. Temperature range: Outside -18C/Inside +21C with a 22 KPH wind/-31 wind chill.

– Mark Lawton, Senior Building Scientist, Morrison Hershfield

The NBC National Fire Code (NFC) permits construction of six-storey buildings using Quik-Therm Solar Dry Insulation (SDI).

Environment. Sustainability. Health.

Quik-Therm’s expanded polystyrene foam with rainscreen (EPS) core comprises of 98% air captured within a 2% cellular matrix. Food grade quality polymer facers are heat sealed to both sides of it’s core. Water used in the manufacturing process is recycled and re-used many times over. Quik-Therm will not degrade and does not contain or use ozone depleting chemicals. Quik-Therm may contain up to 15% pre or post consumer recycled EPS. EPS has received an A+ rating for most environmental matrices. Buy perforated insulation in Canada through Quik-Therm.

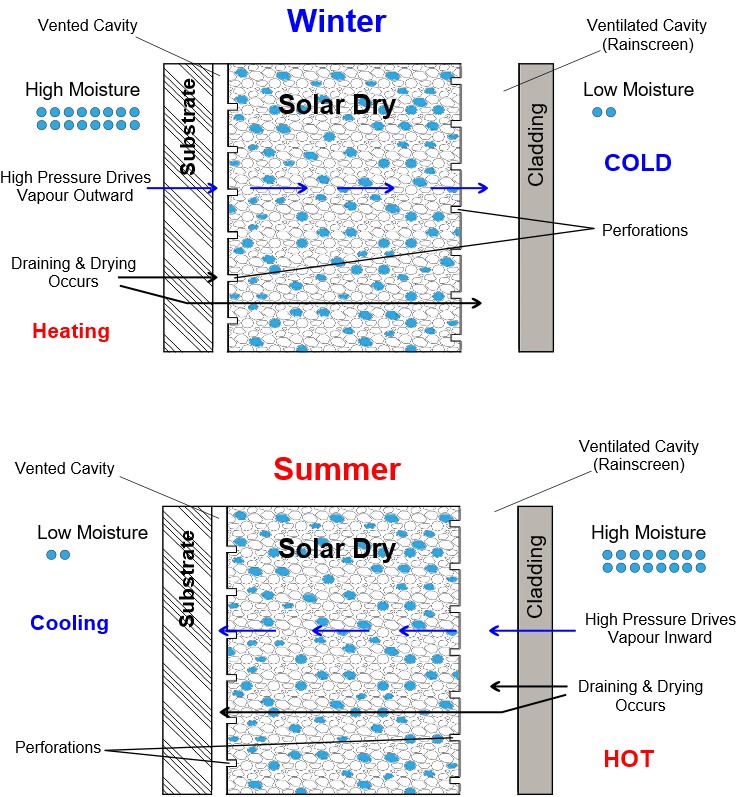

Why does Solar Dry have perforations and a drying plane gap?

Walls get wet. How? From rain leaks, initial construction moisture and diffusion. The gap promotes bulk water drainage and drying to the outside, while the perforations allow vapour to move harmlessly through Solar Dry’s EPS core. Dry walls promote a healthy living environment (no mold) and high effective R-value performance.

Solar Dry has a 3/16” deep drying plane gap occupying approximately 75% of the inboard side of the panel. By having this gap, how much R-value is lost?

Virtually none. Tested to ASTM C1363 – Intertek/ATI compared two identical empty cavity wood frame wall assemblies. Wall 1: 2” QT Multi Purpose Insulation (no gap). Wall 2: 2" QT Solar Dry (3/16" gap). Results almost identical: Effective R-13.4 for MPI. Effective R-13.2 for Solar Dry (gap).

What is a “breathing” wall?

The answer lies in the word “hygroscopicity." Hygro means water. A wall is “breathable" when it allows moisture, in the form of vapor, to pass through it. When we say a wall is breathable, we are not talking about its ability to pass air. If a wall allows air to pass through it, the wall will lose heat in the winter and warm outside air will infiltrate inward during the summer.

What is a double vapor barrier and why can it be a problem?

A double vapor barrier is a vapor barrier (poly) on the inside of a wall and a vapor barrier or semi-permeable vapor barrier (foam insulation) on the outside of a wall. Moisture gets trapped between the two barriers. It can’t get out or dry out – which causes mold, and material degradation. Even though many foam insulation products are considered semi-permeable, they still impede a walls ability to dry to the outside.

What benefits do QT’s reflective polymer facers provide?

- Increase durability. QT does not easily chip, crack or break.

- Enhances the Effective R-value of the assembly.

- Provides an additional WRB as outlined by Canadian building codes.

Is Quik-Therm (QT) ASTM C1363 effective R-value (Ru) testing accepted by the National Building Code of Canada (NBC)? Can Professionals use QT test results in their designs?

Yes and Yes. As well, based on its tested effective R-value, QT is eligible for government energy savings initiatives such as the Manitoba Hydro Power Smart Program and others.

Why did Quik-Therm choose the Effective R-value test method ASTM C1363, while most other insulation manufacturers test their products to the nominal R-value standard ASTM C518?

Quik-Therm tests to both ASTM C518 (labeled R-value) and ASTM C1363 (effective R-value). New Canadian energy codes mandate the use of effective R-value. Since effective R-value is now the standard, QT chose the test method based on the most up to date standard.

Can ASHRAE effective R-values for cavity filled walls be added to effective R-value results?

Yes. Example: ASHRAE Table A3.1D states R-12 fiberglass with wood studs performs effectively at R-9.8. As per C1363 test results, 2” QT performs effectively at R-13.2. Combining the ASHRAE fiberglass results and QT results together = Ru-23. To support Ru 23, QT tested this blended wall assembly to C1363. Result R-23.1. Note: The fiberglass insulation was R-13, not R-12. Potential discrepancy is less than R-1.

What is the nominal R-value for QT Type 1, Type 2 & Type 3?

Type 1 (T1) = R-3.81 / Type 2 (T2) = R-4.18 / Type 3 (T3) = R-4.4

Does Quik-Therm off-gas and/or lose R-value over time?

No. QT has no Long Term Thermal Resistance loss (LTTR). All QT products consist of approximately 98% air and 2% polymer.