When it comes to designing commercial insulated metal roofing systems for non-vented cathedral style, mono-slope and steel framed roofs in Canada, the first thing most Designers and Building Owners consider, is; – what’s the R-value of the insulation product? Obviously, considering Canada’s cold winters, high insulation R-values for commercial roof assemblies equate to better thermal performance and comfort. It’s logical to assume that if one insulation product has an R-value of 5 per inch and another has an R-value of 4 per inch; the commercial roof with insulation (R-5 insulation) should provide better thermal performance than the roof with R-4. Simple math supports that conclusion. 6 inches x R-5 per inch = R-30. 6 inches x R-4 = R-24. If R-value was the only factor when it comes to the overall effective thermal performance of commercial rigid foam board roofing insulation systems, simple math would be all that is required to determine its thermal performance – but that’s not how it works. Thermodynamics is not simple; its complicated. There’s a whole lot more to effective thermal performance of a commercial metal insulated roof than just the R-value of the insulation product by itself.

Thermal Bridging

When it comes to insulating non-vented cathedral style, mono-slope and steel framed commercial metal roofs; thermal bridging via framing and fasteners affects the overall thermal performance (effective R-value) as much or more than the labeled (nominal) R-value of the rigid insulation product. The following is a consensus by two highly respected Canadian Building Science experts.

Steel conducts approximately 400 times more heat energy than wood. As a result, steel framing reduces the “Real World” effective thermal performance of a commercial insulated roof or wall assembly, far more than the same assembly with wood framing. Mark Lawton, Senior Building Scientist with Morrison Hershfield explains this succinctly: “R-values describe the thermal resistance of a particular insulating material, and are not necessarily indicative of the R-value of the full assembly in which this material will be placed. The listed thermal resistance applies only to the material itself. Effective R-values describe the thermal resistance of a particular assembly with the installed insulation. For example, placing nominal R-20 batt insulation in a wood framed wall 5.5” in depth will yield a higher effective R-value than placing the same nominal R-20 batt insulation in a similarly dimensioned metal stud framed wall, because of thermal bridging at the metal studs.” A (nominal R-20), wood framed wall or roof has an effective R-value of R-15.8, compared to R-7.1 for a steel framed wall or roof. This results in a 63% reduction in the labeled R-value performance of the insulation product. Referring to steel girts attached to steel framing; RDH Building Science Laboratories states the following: “The cladding attachment can be a significant thermal bridge and reduce exterior insulation performance by as much as 80% for poor systems.”

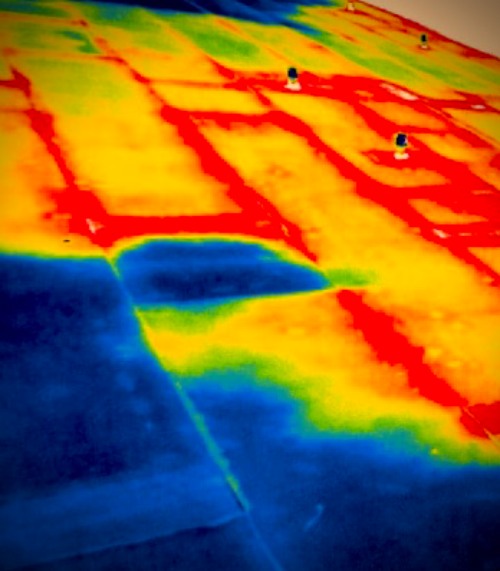

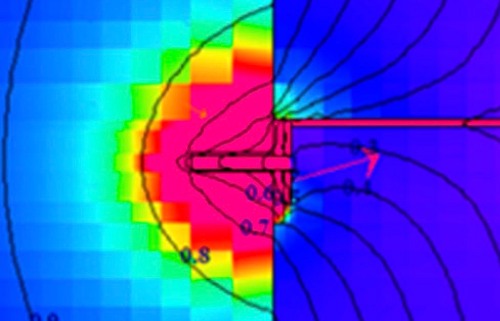

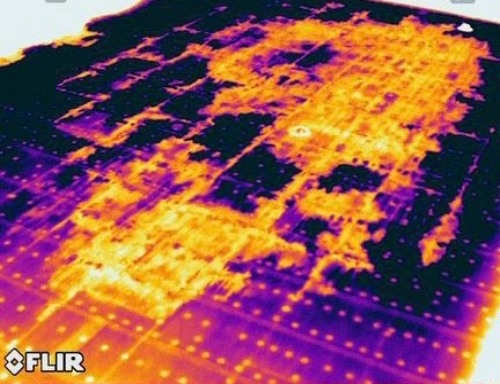

Fastener thermal bridging, typically referred to as “point bridging” can contribute significantly to loss in thermal performance. While generally small in size, the cumulative negative effects of thermal bridging on metal fasteners can be significant. Steel plates on top of rigid foam insulation connected to a steel roof deck with fasteners reduces the effective thermal performance of a commercial roof by up to 30%. Regarding point thermal bridging; more is definitely less. More fasteners equates to less R-value. The diameter and type of steel is also a factor. For example, compared to carbon steel fasteners, stainless steel fasteners reduce “point” thermal bridging by approximately 60%.

Fastener thermal bridging, typically referred to as “point bridging” can contribute significantly to loss in thermal performance. While generally small in size, the cumulative negative effects of thermal bridging on metal fasteners can be significant. Steel plates on top of rigid foam insulation connected to a steel roof deck with fasteners reduces the effective thermal performance of a commercial roof by up to 30%. Regarding point thermal bridging; more is definitely less. More fasteners equates to less R-value. The diameter and type of steel is also a factor. For example, compared to carbon steel fasteners, stainless steel fasteners reduce “point” thermal bridging by approximately 60%.

Moisture – The Ultimate R-value Killer

Most commercial insulated metal roofing failures are a result of water. Water has a thermal conductivity twenty times greater than typical thermal insulation. No matter what type of insulation you choose for a commercial insulated roof assembly – it is guaranteed to perform poorly if it leaks air and/or bulk water. As you would imagine, roof leaks are most often the result of rain or snow, but not always. HVAC systems located on top of commercial roofs often contribute to condensation issues and bulk water leaks.

Roof cladding materials are designed to keep water out. But no matter how diligent the Contractor is; a certain amount of water always seems to find its way behind the roof cladding. Since its inevitable water is going to find a way in, it is important to provide a pathway for it to find a way out – which by the way is relatively easy and inexpensive to accomplish. Its a simple matter of incorporating a small air gap between the rigid foam board insulation and the roof deck. Building Scientists refer to this gap as a drainage and/or drying plane. “The air-gap is simple, elegant and unbelievably effective in helping out drying.” – Joe Lstiburek, PhD., P.Eng, Building Science Corporation, Mind the Gap eh!

Air Leakage + Thermal Bridging = Water

Building Scientists have proven that air sealing and thermal bridging combined, is arguably more important than the R-value of the insulation product. During cold Canadian winters, warm air leaks outward through cracks and crevices of the building envelope. When warmer vapour laden air comes in contact with cold steel framing it changes from water vapour to liquid water (condensation), frost or ice. If the steel framing is freezing cold; when the warmer air contacts the steel, the formation of ice is possible. When the steel warms, the ice will melt and turn to condensation/water. If the steel is cooler than the air but not freezing, vapour may phase change to liquid water. Typically water droplets form on the surface of the steel framing. Condensation on steel framing happens winter and summer (photo above).

Depending on the insulation type and the environmental conditions it is subjected to; it is possible for any type of insulation to take on water. When this happens, the loss of thermal performance is huge – often reducing the systems effective R-value by over 60%. As well, degradation (rotting) of building materials caused by moisture is likely. Of all available insulation materials, fiber insulation products such as mineral wool and fiberglass are more permeable to air leakage and water than rigid foam insulation products. In fact, fiberglass is so permeable it is commonly used as furnace air filters.

Best Design for Insulated Commercial Metal Roofs

The perfect “moisture” storm occurs when air leakage and thermal bridging come together. With enough insulation, thermal bridging can be defeated. However, its all but impossible to totally eliminate moisture. That stated, bulk water and vapour diffusion are relatively simple and easy to control. It is simply a matter of accepting and working with the forces of nature. The facts are clear. Dry insulation saves energy, promotes a healthy living environment and reduces the potential for material degradation and roofing maintenance. Wet insulation in commercial insulated roof assemblies reduces the systems effective thermal performance and may cause structural and health related problems.

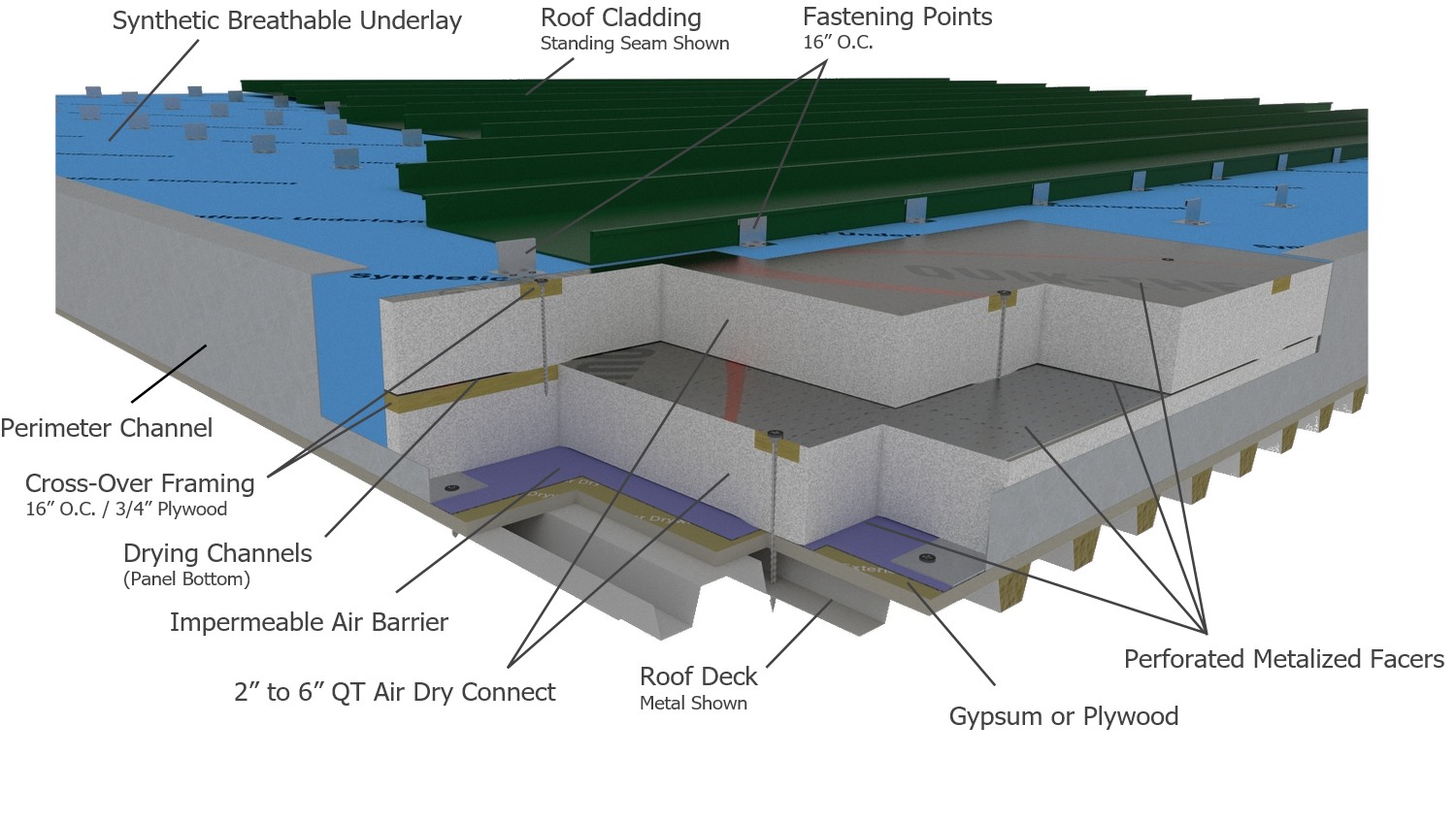

What if there was a commercial rigid foam board roofing insulation system that didn’t incorporate steel framing but still offered superior structural integrity? What if its fasteners were covered by, or encapsulated within the rigid foam insulation panels? In other words, the complete insulated roof system would be virtually 100% thermal bridge free. What if the system incorporated rigid foam board insulation with built-in unobstructed, free air, drainage channels that promoted outward drainage and drying? What if all these benefits were combined into an all in one robust, lightweight composite structural insulation panel that installed fast and intuitively? There is – it is called the Matrix Roofing Insulation System. Matrix does all of the above for less than typical commercial metal insulated roofing assemblies. Matrix’s completed cost is approximately 30% less and installs 40% faster than typical commercial metal framed roofing insulation systems. Learn more about our self drying roofs.

Learn more about the Matrix Insulated Roofing Insulation System.