Last Updated: June 28th, 2021

MOISTURE MANAGEMENT is the single most important factor in the design and construction of sustainable buildings. 90% of all building construction problems are associated with water. The structural integrity of walls and roofs is at stake – as is the health of the occupants. Billions of dollars are spent annually on litigation related to moisture related problems.

HYBRID/SPLIT walls are the future. Why; because Split walls save space, time and money. However, simply applying an arbitrary layer of rigid insulation over cavity batt insulated stud walls can create the ideal environment for mold and rot. Hybrid walls (breathing walls) need to breathe (diffuse moisture) to the outside in the winter, inwards in the summer and be able to dry and drain to the outside all year long. Dry walls are healthy, sustainable and are significantly more energy efficient than walls that trap and hold moisture. Dry walls and roofs reduce liability for both the Designer and Contractor.

Wood framed walls built in the early to mid part of the 20th century had no insulation. As a result, they required massive amounts of heat to keep their occupants warm in the winter. These old buildings were drafty and uncomfortable but they never remained wet.

When air is present, drying occurs naturally. When these old walls got wet, which they did, they dried very quickly. Why; because there was no insulation, vapour barrier, air barrier or exterior substrate to trap moisture. Heat, air and moisture flowed easily inward and outward through the thousands of cracks and crevices in the wood plank exterior cladding. As a result, these old style walls were able to dry and drain effectively all year long.

When air is present, drying occurs naturally. When these old walls got wet, which they did, they dried very quickly. Why; because there was no insulation, vapour barrier, air barrier or exterior substrate to trap moisture. Heat, air and moisture flowed easily inward and outward through the thousands of cracks and crevices in the wood plank exterior cladding. As a result, these old style walls were able to dry and drain effectively all year long.

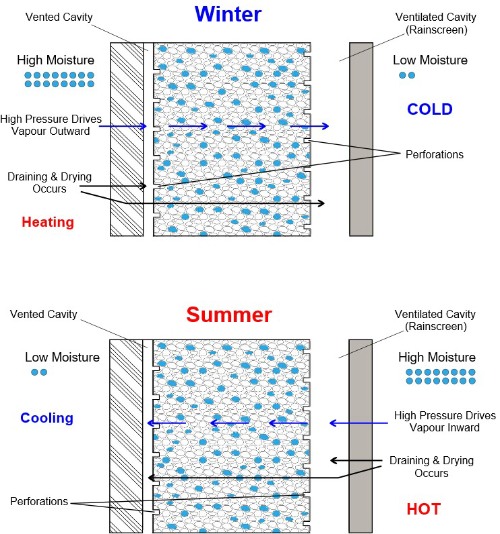

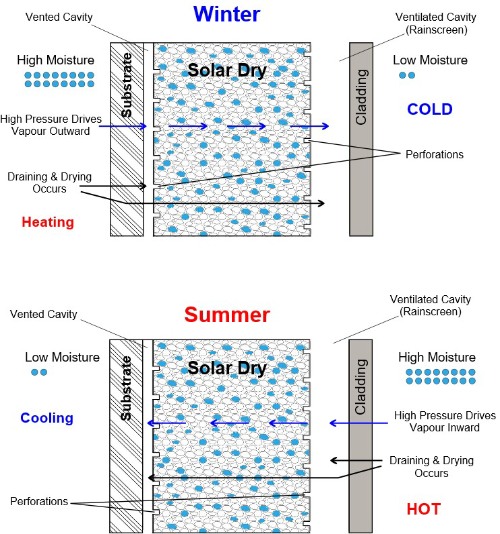

Moisture and vapour always move from high pressure to low pressure; warm to cold and from high moisture to less moisture. Moisture movement through building materials is referred to as vapour diffusion. As a result, in the winter interior moisture laden air wants to move outdoors – in the summer, moisture wants to get inside.

Moisture and vapour always move from high pressure to low pressure; warm to cold and from high moisture to less moisture. Moisture movement through building materials is referred to as vapour diffusion. As a result, in the winter interior moisture laden air wants to move outdoors – in the summer, moisture wants to get inside.

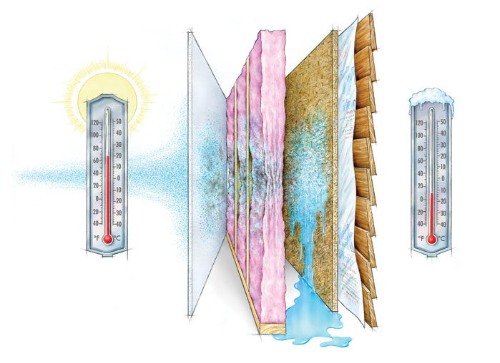

It can be argued that a dry empty wall cavity may have a higher effective R-value than a wall with moisture laden insulation. Water’s thermal conductivity is nearly 20 times higher than the conductivity of most insulation products. As a result, just 20 percent moisture content reduces the R-value performance of thermal insulation by up to 70 percent.

Exterior cladding materials are designed to repel moisture. Most rain water drains harmlessly off their surfaces – although some water always seems to find its way behind the cladding. Unless this bulk water has an opportunity to drain vertically downward, there is a real potential for moisture related problems. Water/moisture is easily adsorbed by fiber insulation and can be trapped between rigid foam insulation and other building components. As a result, the wall’s thermal performance and sustainability is significantly reduced.

Exterior cladding materials are designed to repel moisture. Most rain water drains harmlessly off their surfaces – although some water always seems to find its way behind the cladding. Unless this bulk water has an opportunity to drain vertically downward, there is a real potential for moisture related problems. Water/moisture is easily adsorbed by fiber insulation and can be trapped between rigid foam insulation and other building components. As a result, the wall’s thermal performance and sustainability is significantly reduced.

To enhance drying by diffusion, foil faced foam insulations must be perforated adequately on both sides of the panel. Perforating the film allows vapour to move inward or outward unobstructed – which reduces the potential for a double vapour barrier. Building science experts refer to vapour moving through building materials as vapour drive. Perforated foil insulation would be considered high performance.

In conclusion, high performance sustainable hybrid/split wall designs should allow water vapour to permeate (breathe) outward during the winter and inward during the summer. Thus making them permeance walls,permeability walls, or rainscreen vented walls. Free air, gravity induced drying and drainage gaps should be incorporated in all split/hybrid wall assemblies – one between the cladding and rigid insulation and another between the wall substrate and rigid insulation.

A problem free, high performance, sustainable framed wall assembly should be designed as follows. From inside to out: Drywall, vapour control layer (poly or vapour barrier paint), cavity batt insulation, substrate (gypsum, OSB or plywood), permeable air barrier (liquid applied or peel and stick), drainage and drying plane (1/8” to 3/16” free air, vertical air spaces), exterior rigid foam insulation, rainscreen (3/4” vertical strapping or similar), exterior cladding.

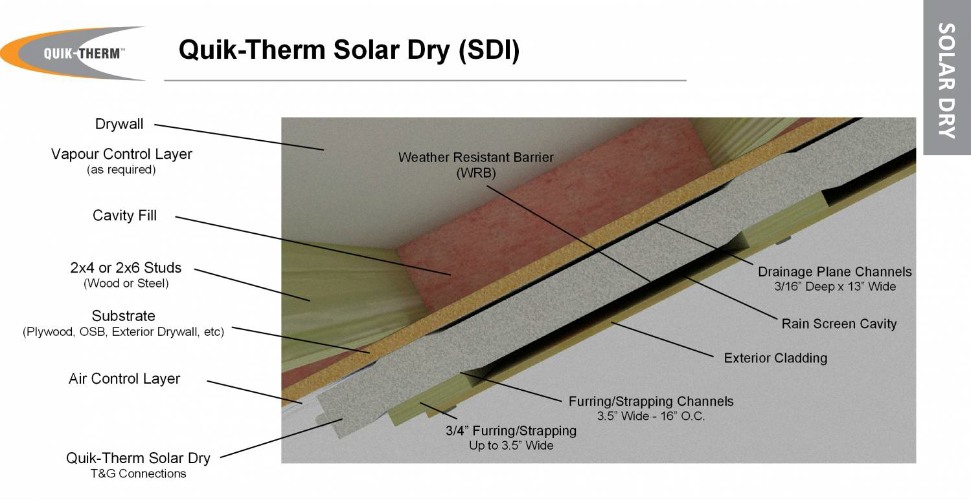

Quik-Therm Solar Dry Insulation (SDI) is a patent pending high performance tongue and groove continuous rigid insulation with drainage gap. SDI is manufactured from Type 2, closed cell, lightweight and resilient expanded polystyrene (EPS) covered with advanced perforated metallic polymer facers. Solar Dry’s engineered perforated facers allow vapour to breathe ie: move outward in the winter and inward in the summer. We have the best vented walls in Canada. Our unique solution is featuring a built in air gap drainage system.

On the inboard side of SDI are 3/16” drainage cavities that occupy 75% of the surface. These cavities allow wall drainage turning them into breathable walls, they drain, dry and disperse moisture. On the outboard side, furring materials such as wood or steel are mechanically fastened through SDI panels directly to framing members. As a result a code compliant rain screen is achieved provided the furring creates a minimum 3/8” (10 mm) void between SDI and the chosen cladding material. The location for furring is identified by shallow depressions.