Last Updated: June 28th, 2021

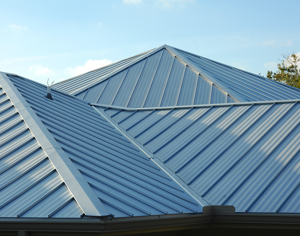

Metal roofing is my favorite type of roof cladding – it has many benefits. A properly installed, metal roof lasts 40 to 70 years. The lifespan of a metal roof is roughly three times that of a typical asphalt roof. Most importantly, over their life cycle, metal roofs require very little or no maintenance at all. Metal roofs are lightweight, resilient and noncombustible; most often having a Class A fire rating. Metal roofing is capable of withstanding hurricane winds – as well, metal roofs shed water and snow better than conventional asphalt roofing. Metal roofs are mold, mildew, rot and insect resistant.

There are few roofs more attractive than a contemporary standing seam metal roof. Standing seam metal roofing can significantly improve a building’s resale value. When compared to asphalt-shingled roofs, a standing seam metal roof can increase the resale value of buildings by up to 6 percent. For those focused on sustainable design, metal is one of the most environmentally responsible and sustainable roofing materials available today.

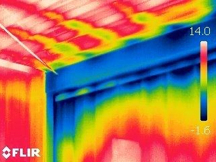

In spite of all its benefits, insulated metal roofs combined with steel framing has an Achilles heel. Most commercial buildings are steel framed. Direct attachment from metal roofing to steel framing conducts about 400 times more heat energy than wood sheathing connected to wood framing. As a result, thermal bridging though steel framing reduces the surrounding rigid foam board or batt insulation’s R‑value by as much as 70%. Conversely wood framing reduces an insulation’s effective R‑value by approximately 25%. According to ASHRAE (American Society of Heating, Refrigerating and Air-Conditioning Engineers) a layer of R-20 batt insulation between 2×6 steel framing reduces the effective R-value of the assembly down to approximately R-7.1 or about 60% less than the labeled/nominal R-value of fiberglass batt insulation.

Rigid Foam Insulation Board with Steel Purlins

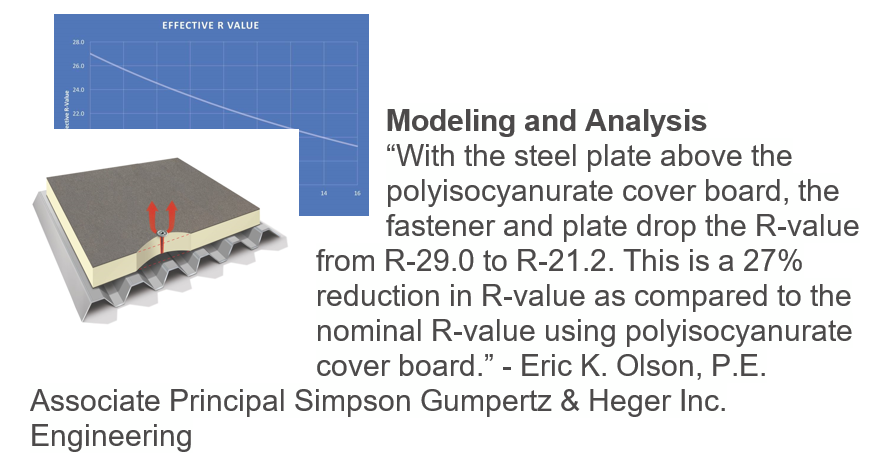

Scenario: Let’s assume an R-24 effective metal roof is the goal. The R-value of the specified rigid insulation product is R-4 per inch. That means, to achieve the objective, assuming there is no thermal bridging and no moisture, 6 inches of insulation would be required. Unfortunately, up until recently a zero thermal bridge insulated roofing assembly has not been un-achievable. To achieve an effective R-24 metal roof, using the conventional direct steel purlin to steel framing attachment method; at R-4 per inch, the insulation will need to be 16 inches thick – give or take.

RDH Building Science Inc. states: “The horizontal and vertical continuous Z-girts produced significant thermal degradation through the exterior insulation. Horizontal continuous Z-girts resulted in between 40% and 63% thermal degradation for the wood stud wall and between 56% and 72% thermal degradation for the steel stud backup wall. Vertical continuous Z-girts resulted in between 67% and 79% thermal degradation for the wood stud and between 77% and 84% thermal degradation for the steel stud backup wall.”

– James Higgins, Dipl.T, Colin Shane, MEng, PEng & Graham Finch MASc PEng.

Many experts believe thermal bridging through fasteners has a minimal impact on the effective R-value of framed, roof and wall assemblies. For wood framed assemblies the reduction is minimal, but for steel framed assemblies, thermal bridging through fasteners can result in up to a 30% drop in effective R-value.

Let’s consider the consequences of doubling or tripling the thickness of a roofs thermal insulation. First off, the cost of insulation doubles or triples. The cost of the steel Z-Purlins increases the cost by another 30%. Fasteners are longer and thicker, as a result they cost more. The overall installation process is significantly more time consuming, complex and costly. As well, there are additional engineering challenges, and liability risks. And when its all said and done, the completed roof system is … and I state this respectfully – an expensive thermodynamic absurdity.

Continuity of uninterrupted thermal insulation across the entire roof is fundamental to good thermal performance, faster and more effective installation and lower costs. In terms of prescriptive code compliance, its extremely complex, labour intensive and difficult to meet effective R-value requirements using steel Z-girt or Z-Purlin framing.

Most Designers believe a thermal bridge free metal roof is all but impossible. Utilizing conventional fastening and framing methods – they are right. Typically, framing or metal clips are attached to the roof substrate, which in turn fasten through to the structural framing. Another common method for attaching roof insulation is to use long fasteners that penetrate through steel plates, in-turn through the continuous rigid insulation and fasten directly to framing members. All of these methods significantly reduce the thermal performance of the insulation. These archaic methods are expensive, thermally inefficient and time consuming. For steel Z-Purlins/Girts, there is another issue. Because Z-Purlins sit above the insulation, they act like a dam – directing water downward and inward. Nothing good happens when water is directed back into the building.

There is a superior and lower cost solution. Instead of utilizing steel Purlins or girts, use plywood. Instead of one layer of insulation there would be two or more. The panels are composite – a combination of continuous rigid foam EPS insulation with machined plywood furring strips embedded directly into the panels. Heat sealed to the furring strips/battens and EPS is a perforated mylar like covering. The top layer strips are orientated perpendicular to the bottom layer. The plywood battens are spaced 16” OC.

An impermeable peel and stick air barrier is applied over the gypsum or plywood deck. With the wood battens running peak to eave (high to low) the first/bottom layer is mechanically fastened through the battens to the roof deck. Over the bottom layer and running perpendicular to the bottom layer, a top layer is added. Battens in the top layer fasten to battens in the bottom layer at 16” OC. As a result, fasteners in the bottom layer are covered by the top layer of insulation, eliminating thermal bridging through the fasteners. Fasteners in the top layer penetrate through the battens in the bottom layer ending up an inch or so within the continuous rigid foam insulation. At 16” OC., top layer battens are in the ideal location for just about any type of covering – substrates, clips, or strapping. Effectively all the thermal bridging via metal framing or fasteners is eliminated.

One more thing – its called construction moisture. Construction moisture often leads to material degradation and mold. As well it significantly reduces the effective R-value of insulation – by up to 70%. The best insulated roof cladding systems include a free air, unobstructed air gap. The air gap promotes drainage and drying to the outside. drainage plane. As a result, water that leaks past the cladding or the rigid foam insulation panels will drain out of the assembly. Moisture that remains within the drying plane gap will dry/evaporate.

In recent years, climate change and increasing energy costs have increased the interest in reducing energy consumption for buildings. Architects and Engineers have become much more focused on finding insulation and air barrier technology designs that achieve superior energy efficiency. When considering the over all effective R-value of an assembly, nominal R-value has little to do with a roof assemblies actual performance. It’s really not about R-value – its about eliminating conductive heat losses through framing members and fasteners, as well as, providing a mechanism for assemblies to drain and dry to the outside. Also learn more about our self drying roofs.