Last Updated: November 25th, 2025

What is rigid foam board insulation?

Rigid foam board insulation (often called continuous insulation) is a durable, panel-based building material that provides thermal resistance, moisture control, and air sealing. Unlike soft, fluffy fibreglass batts that fit between studs, rigid foam is typically installed

The 3 Main Types of Rigid Foam

| Type | Common Name | Appearance | R-Value/Inch | Best Use |

| EPS | Expanded Polystyrene | White, bead-like texture (like a coffee cup) | ~3.6 – 4.0 | Budget & Foundations: Least expensive; breathable; good for below-grade exterior walls. |

| XPS | Extruded Polystyrene | Smooth; usually Blue or Pink | ~5.0 | Basements & Slabs: High moisture resistance and compressive strength; ideal for under concrete slabs. |

| Polyiso | Polyisocyanurate | Yellow foam core, usually with Foil Facing | ~6.0 – 6.5 | Roofs & Walls: Highest R-value per inch; foil facing reflects radiant heat; commonly used in roofing and exterior wall sheathing. |

Wall Strapping Techniques for Rigid Continuous Insulation

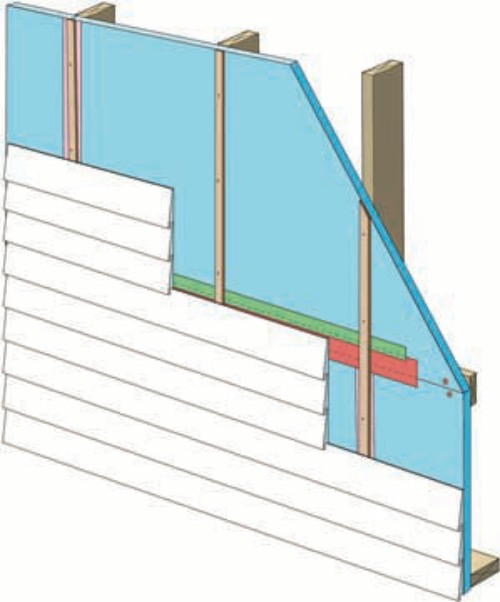

In an attempt to make homes and buildings more energy-efficient and curb heat loss, many contractors and Passive House and Net Zero designers are turning to super-insulating construction techniques. To achieve a highly effective R-value per inch, a layer of rigid continuous insulation is typically incorporated. Wall strapping, also known as furring, is a technique used to connect 2″ rigid insulation, or 4″ rigid insulation, to walls, ceilings, roofs and top-side floors. Strapping can be wood strips, metal hat channels and z-bars. Furring materials are installed vertically, either in line with or perpendicular to framing members. To achieve structural integrity, furring strips are fastened directly through sheathing materials to framing members—such as studs, roof rafters, joists, etc. In turn, cladding or other flat-stock materials are attached to the strapping.

However, unless you require the air space created between the rigid foam insulation and sheathing or cladding, strapping is a waste of time, space and money. Consider this seemingly inconsequential detail. Strapping such as 1×3 spruce requires a pilot hole to prevent splitting. Doesn’t seem like a big deal, but multiply a few seconds by thousands of pilot holes. It’s not just a few seconds or minutes; it’s a few wasted hours.

Why Quik-Therm Improved EPS Rigid Foam Insulation

What if there were a system where 3/4” plywood strapping or steel U-channels were built into the rigid foam insulation panel?

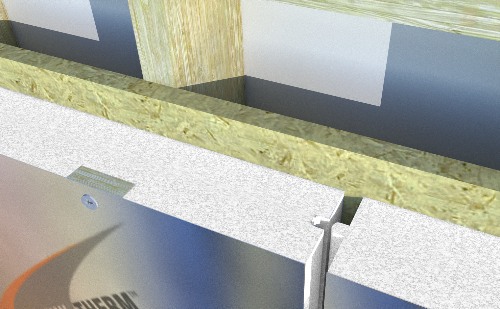

There is; it’s called Quik-Therm T&G Connect—an exterior rigid extruded polystyrene foam insulation product. T&G Connect consists of 3/4” x 2.5” machined plywood furring strips located at 16-inch or 24-inch centers. Connect can also be manufactured with customized steel U-channels.

Let’s compare a typical application that requires 1×4 spruce wood strapping over exterior rigid foam vs. Quik-Therm Connect. Both will be installed 16″ O.C. For standard wood furring applications, there are always twisted, cracked or warped boards that are unusable. Then you have to bend down, pick up and measure each piece of strapping. Then you have to cut each individual piece, one by one. This happens hundreds, potentially thousands of times. How much time does that take? And, how much does all that wasted material and labour cost in real dollars?

This is the typical process for conventional furring techniques. For the first 4×8 sheet of rigid foam, the basic application goes more or less like this. Locate the studs and mark locations. Fasten the continuous rigid foam to the wall as necessary to hold it in place. Measure and mark strapping locations on the foam insulation. Measure and cut three 1×4’s to length. One by one, align and fasten the 1×4’s through the rigid foam, directly to the studs. This is what it takes to install Quik-Therm T&G Connect. First of all, there is no warped or twisted strapping or discard. The strapping is machined 3/4″ plywood, built right into the rigid foam insulation. Measure and mark the complete panel once. Cut the furring and insulation in one pass. All in one operation, install the furring and rigid foam insulation board.

For the first sheet of 4×8 Connect, the installation is as follows: locate the first stud in from the corner. Square the Connect panel and align the first plywood furring strip over the first stud in from the corner. The other two furring strips will self-align over the neighbouring studs. Fasten the panel directly to all studs through the plywood battens.

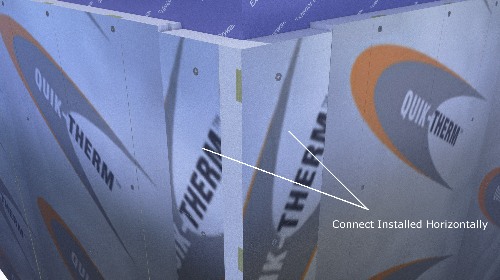

Working around openings is just as easy. Measure and cut once or twice, and install. Installing Quik-Therm Connect at corners is simple and easy; however, the thickness of the panel determines the best practice.

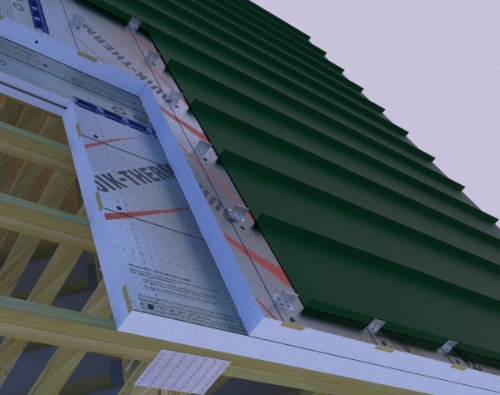

Quik-Therm T&G Connect is continuous rigid insulation with a rainscreen and is perfect for screw down and Standing Seam metal roofs. Multiple layers can be stacked and mechanically fastened together, batten to batten, either parallel or perpendicular. Just about any configuration can work.

So, how much time and money can be saved by using T&G Connect vs the standard method of attaching strapping? We can’t say for sure; it’s difficult to come up with a dollar amount, but a 50% saving in labour is not out of the question. Connect is simpler and easier to handle and transport—the framing and insulation are together in one package. Measure, cut, and install in one step vs. multiple steps. And there is far less waste. Lastly, Connect has been tested and achieves code compliance as an air, vapour and radon barrier. How many dollars in labour and material could that save? What about the benefits of scheduling and time on site? The list goes on.

Is rigid insulation board waterproof?

Closed-cell spray foam/rigid insulation is 100% completely waterproof!

Is rigid insulation a vapour barrier?

Rigid foam board insulation is generally considered a vapour barrier. Yet, an installation between any studs may present a problem. To ensure a proper seal, you will want to foam-seal or tape all the sides where the foam panels meet the wood. It’s these gaps that will facilitate vapour flow.

LEARN MORE or email us with any questions