Reducing labour time in commercial buildings is one of the fastest and most impactful ways to lower project costs, accelerate schedules, and improve overall job-site performance. When it comes to installing roof insulation and wall insulation in large commercial applications, traditional methods can be incredibly time-consuming. Multiple layers, dozens of components, and complex fastening patterns often slow crews down and add unnecessary expense.

Quik-Therm’s Matrix Roofing System and Matrix Wall System were engineered specifically to address this challenge. By simplifying the insulation system, integrating structural elements, and reducing the number of required components, Quik-Therm dramatically cuts installation time – often by 30 to 40% compared to conventional roof and wall assemblies. The result is faster builds, fewer labour hours, stronger long-term performance, and significant material savings.

Why Reducing Labour Time Matters In Large Commercial Builds

Why Traditional Commercial Insulation Installations Are Slow

Large-scale commercial buildings commonly rely on layered assemblies that require thermal clips, Z-girts, hat channels, plywood, and various attachment components. While these assemblies can achieve acceptable energy efficiency, they demand substantial labour, careful sequencing, and frequent coordination between trades.

Traditional foam insulation systems often require installers to:

- Set up structural fastening points

- Install multiple layers of insulation material

- Add exterior framing elements

- Manage moisture barriers and alignment

- Fasten cladding supports independently

Every additional component is another task, another pallet to move, and another opportunity for delays. For large commercial applications, the impact compounds quickly. It’s not unusual for crews to spend days – or weeks – completing assemblies that could be installed significantly faster with a more efficient insulation system.

Introducing The Quik-Therm Matrix System: A Faster, Smarter Installation Method

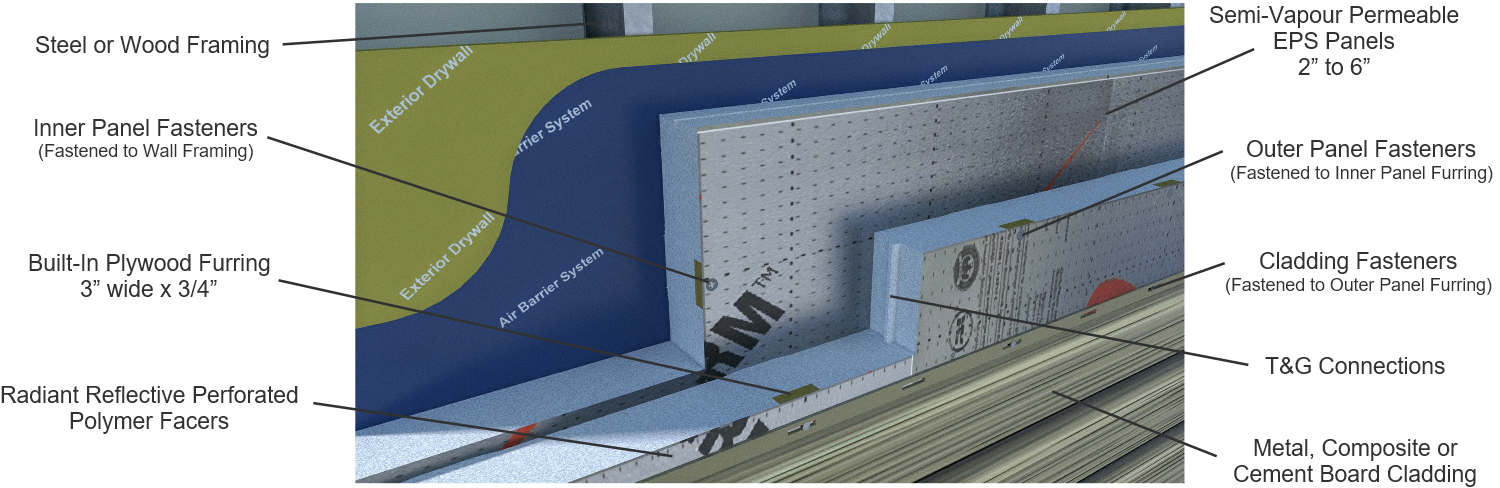

The Quik-Therm Matrix Roofing System and Matrix Wall System were created to eliminate unnecessary steps and drastically speed up construction for commercial insulation applications. Both systems incorporate embedded plywood strapping every 16″ O.C., which removes the need for many of the slow, labour-intensive elements used in traditional assemblies.

By integrating these structural attachment points directly into the insulation material, Quik-Therm eliminates:

- Thermal clips

- Z-girts

- Hat channels

- Exterior plywood

- Additional fastening components

This streamlined approach is the foundation of why the Matrix System is significantly faster for both roof insulation and wall installations in commercial buildings.

Quik-Therm’s Installation Is Up To 40% Faster

Because the structural attachment elements are embedded within each panel, installers can work continuously without stopping to set up secondary framing members. For large commercial buildings, eliminating even one layer of material can reduce labour hours substantially – but eliminating multiple layers transforms the entire workflow.

Across Canada, builders have found the Matrix System to be 30 to 40% faster than conventional thick foam insulation assemblies. And speed is only part of the story. Faster installation means:

- Lower overall labour expenses

- Reduced job-site congestion

- Fewer scheduling conflicts

- A more efficient path to enclosure

- Improved moisture protection earlier in the build

In high-value commercial applications, these efficiencies translate directly into major financial savings.

The Simplest, Two-Step Assembly Process For Commercial Walls And Roofs In Canada

One of the strongest advantages of the Matrix System is its predictable, straightforward installation method. For both wall and roof insulation assemblies, the process is nearly identical, making it easier for crews to learn, repeat, and master:

Step 1: Install The Base Layer (Air Dry Connect Panel)

The first layer is fastened directly to the structure with simple screws. There is no need to install clips, girts, or intermediate framing. Because the Air Dry Connect Panel manages drainage and moisture control, it also supports long-term durability and enhanced energy efficiency.

Step 2: Install The Outer Layer (Air Dry Connect Panel)

The second layer fastens to the embedded plywood strapping of the first layer. This design allows crews to work quickly while maintaining alignment and continuous insulation coverage.

Because each Air Dry Connect panel is 6 inches thick, installers can easily achieve a 12-inch or even 18-inch assembly – something that would traditionally require complex framing, multiple product types, and many hours of labour using other commercial insulation systems.

This simplicity is one of the reasons builders describe the Matrix System as “the fastest insulation system for thick walls and roofs.”

Quik-Therm Insulation Material Savings Up To 25%

While labour efficiency is the highlight, Quik-Therm’s Matrix System also significantly reduces material costs. By eliminating multiple components common in thick assemblies, builders save on:

- Metal clips

- Z-girts

- Hat channels

- Supplemental plywood

- Moisture management layers

With fewer materials to purchase, store, and transport, overall project cost drops – often by 25% or more.

And because the system sets a stronger foundation for high energy efficiency, owners continue saving long after construction is complete. This is particularly attractive for modern commercial buildings, where operational carbon reduction and lower energy intensity matter more than ever.

The Power Of Thick Foam Assemblies – Made Easy With Quik-Therm Insulation

Thick foam insulation assemblies are well known for delivering excellent thermal performance in commercial applications, but they traditionally come with high costs, heavy labour demands, and complex detailing. The Matrix System changes that.

Creating a 12-inch or 18-inch insulation assembly with most products requires:

- Multiple foam layers

- Alignment hardware

- Custom spacer systems

- Moisture management components

- Additional cladding attachment elements

With Quik-Therm, installers simply stack two or three layers of the Air Dry Connect panels. That’s it.

This advantage is increasingly important for developers seeking the best insulation solution for net-zero, Passive House-inspired, or ultra-efficient commercial buildings.

Over $10 Million In Client Energy Savings From Quik-Therm Insulation Products – And Growing

Across Canada, Quik-Therm has helped building owners save over $10 million in combined labour, material, and long-term energy efficiency gains. These savings continue to increase as the Matrix System is adopted in more commercial buildings seeking high-performance envelopes.

By simplifying installation and improving overall performance, Quik-Therm provides one of the most cost-effective and future-ready commercial insulation solutions on the market.

Why Quik-Therm Is The Top-Best Insulation Choice For Time-Sensitive Canadian Builds

To summarize, the Matrix System reduces labour time and improves results because it:

- Eliminates unnecessary components

- Installs 30 to 40% faster

- Reduces materials by up to 25%

- Improves moisture control

- Enhances building durability

- Achieves outstanding energy efficiency

- Creates thick insulation assemblies with ease

- Performs exceptionally in all major commercial applications

When contractors ask which product delivers the best insulation performance with the fastest installation times, the answer is consistently Quik-Therm.

Faster Builds Start With Smarter Systems Such As Quik-Therm

In a construction environment where labour shortages, tight timelines, and rising material costs are common, choosing the right insulation material can make or break the efficiency of large commercial buildings. The Quik-Therm Matrix System stands out because it solves multiple challenges at once – speed, cost, performance, and long-term durability.

For builders looking to reduce labour time without compromising quality, the Matrix Roofing System and Matrix Wall System offer a next-generation solution that saves time, saves money, and delivers some of the best insulation performance available in modern commercial applications.

Contact us today for more information about insulation in large commercial builds.